A Local Exhaust Ventilation (LEV) system is a type of engineering control used to capture and remove airborne contaminants at their source, preventing their dispersion into the worker breathing zone. It is designed to protect workers from exposure to harmful dust, fumes, vapours, or other airborne contaminants that may be generated during various industrial or manufacturing processes. LEV systems are commonly used in settings such as factories, laboratories, and workshops where airborne pollutants are a concern.

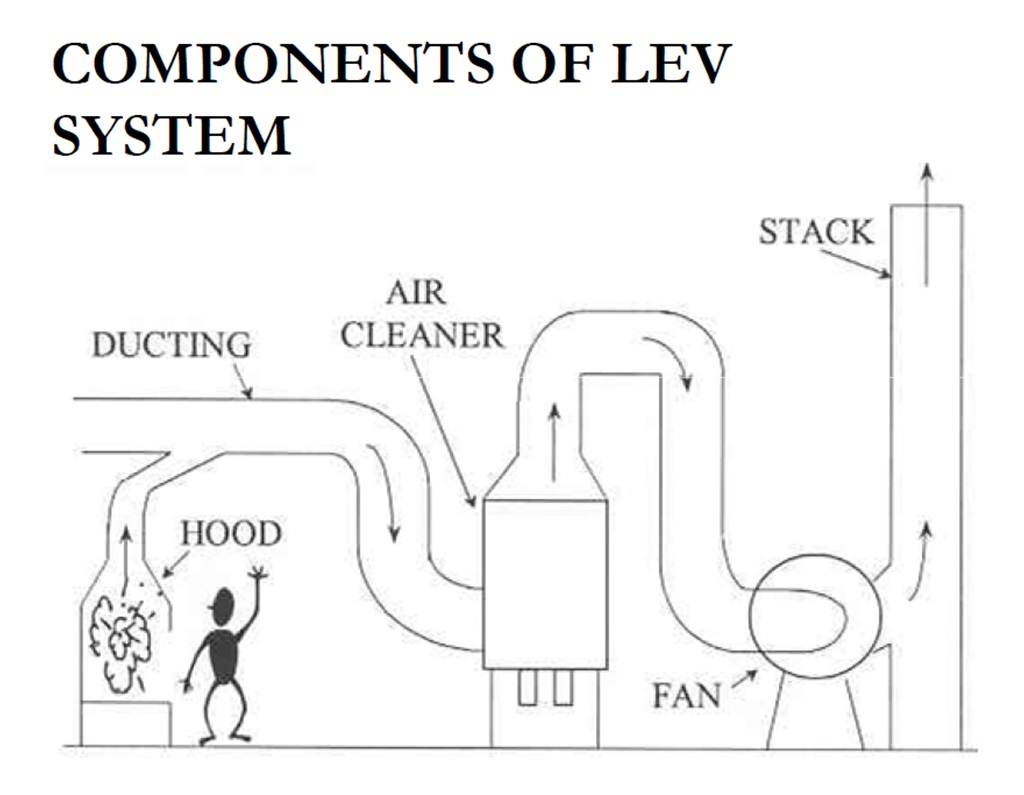

The key components of a local exhaust ventilation system typically include:

1. Capture Hood: This is the part of the system closest to the source of the contaminant. It captures the contaminated air as it is released at source, such as from a machine or process.

Example of Hoods: Ducted/Ductless Fume Hood, Canopy Hood, Extraction arm

2. Ducting: The captured air is then transported through a system of ducts, which may be made of various materials.

3. Air Cleaning Device: Depending on the type of contaminant, the air may pass through filters, scrubbers, dust collectors or other devices to remove or dilute the contaminated air.

4. Fan: A fan or blower is used to create negative pressure within the system, drawing the contaminated air away from the source, through the ducts and air cleaning devices until discharge point.

5. Discharge Point: The purified or diluted air is typically released safely outside the workplace through chimney/stack or may be recirculated if it meets air quality standards.

What are The Regulatory Compliances Related to The Local Exhaust Ventilation (LEV) System?

Department of Environment (DOE) – Environmental Quality (Clean Air) Regulations 2014, CAR 2014:

Regulation 5

– To Prepare proposed design documents and submit Written Notification to DOE (1st submission)

Regulation 7

– The LEV System design need to follow DOE specifications.

– The LEV System design need to be endorsed by Professional Engineer (IR. Engineer).

– The LEV System need to be maintained and supervised properly.

– To Prepare as-built design documents and submit Written Declaration to DOE (2nd submission) after installation completed.

Regulation 9

– Owner to conduct performance monitoring of the LEV system.

– Owner to be equipped with instruments or measurement devices to conduct the performance monitoring.

Regulation 10

– Owner to maintain the LEV performance monitoring record for at least 3 years of latest record.

Regulation 16

– The 1st Chimney Emission Monitoring to be conducted between 3-6 months after operation of the LEV system. Then, the monitoring to be repeated annually unless stated otherwise.

Department of Occupational Safety and Health (DOSH) – Occupational Safety and Health (Use and Standards of Exposure of Chemicals Hazardous to Health) Regulations 2000, USECHH 2000:

Regulation 17

– Owner to conduct inspection and performance monitoring of the LEV system, at least once per month.

– The LEV System need to be examined and tested by HT2 annually.

Regulation 18

– The LEV System design need to be designed according to acceptable standard, endorsed by Professional Engineer (IR. Engineer).

– The LEV System design need to be commissioned after installation to meet design specifications.

Regulation 19

– Owner to keep all records of LEV Test (Regulation 17). A good practice is at least 5 years of latest record.

– Owner to keep all records Design Documents (Regulation 18). Normally the design documents are the Written Notification and Written Declaration document submitted to DOE as per CAR 2014.

What are The Services Dsigntory Offer?

1. DOE Written Notification & Written Declaration

a. Design consultation and calculation based on DOE acceptable standards.

b. Design documents to be endorsed by Professional Engineer (IR. Engineer).

c. Prepare necessary documents and submit to DOSH.

2. LEV Assessment by Hygiene Technician 2 (HT2)

a. Conduct Hood, Duct, Fan and Chimney performance assessment.

b. Prepare report and submit to DOSH

3. Supply of performance monitoring equipment and measurement devices.

4. Guidance on how to perform performance monitoring of the LEV system.